Contact Us

Ningbo Rocking Group Co.,Ltd.

Ningbo Rocking Import & Export Co.,Ltd.

Group Add: No.168 Canghai Road, Hi-tech Industry Zone, Ningbo, Zhejiang Province, China.

Head office Add: Office 1203, NO.1 building of powerlong plaza, Hi-tech district, Ningbo, Zhejiang province, China.

TEL: 0086-574-87162491

FAX: 0086-574-87162492

Mobile: 0086-13906618727

Wechat: 0086-13906618727

Whatsapp: 0086-13906618727

Web: www.rockinggroup.com

E-mail: sales@rockinggroup.com

Introduction

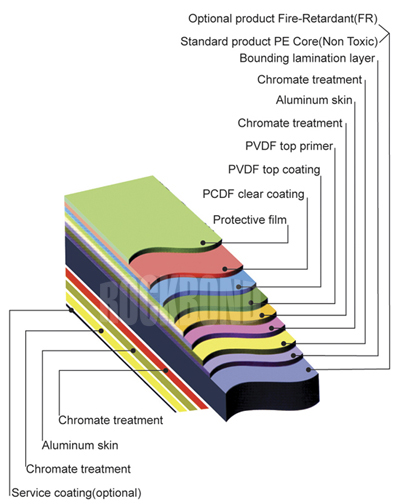

Aluminum composite panel is a revolutionary and  versatile

versatile

decorative panel

for use in curtain wall and cladding applications.

It offers fresh, modern,

beautiful,

creative and practical design possibilities for a variety of applications, for modern

high-rise buildings satisfying every need of architects, engineers, contractors and

building owners.

Standard:

According :GB/T 17748-2008, UKAS, ISO 9001:2000, ASTM

Specification:

Aluminum skin thickness: 0.50x0.50mm 0.40x0.40mm

0.30x0.30mm 0.21x0.21mm

0.18x0.18mm 0.15x0.15mm

Width:1220mm,1570mm(Maximum)

Length:2440mm,upon customer’s request.

Standard Size:

1220(Width) x2440(Length)

Thickness:2mm,3mm,4mm,5mm,6mm

Normal Color:

48 kinds

Non-standard sizes and special colors are available

According to customers’request.

Application Scope:

1)Building exterior curtain walls

2)Decoration reformation storey-addition for old buildings

3)Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4)Shop’s door decoration

5)Advertisement boards, display platforms and signboards

6)Wallboards and ceilings for tunnel

7)Industrial material, vehicle and boat materials

Characteristics:

| 1) High Peeling Strength panel is cross link under high temperature with high-performance and molecular binding materials, which reaches the best level for the important feature high peeling strength. |

|

| 2) Superior Weathering Resistance By means of KYNAR500 based PVDF coating resin, panel possess some superiorities in corrosion resistance, alkali resistance, chalking resistance of ultraviolet light. When exposed to the heat of tropical sunshine or the cold of frigid snowstorm, the panel never loses its colorful appearance. |

|

| 3) Light Weight and Easy for Process panel is easy to process for its light weight(3.5-5.6kg/m2)which can decrease the loss during an earthquake. The processing such as cutting, planning, bending to arc and several configurations in right angle can be done by some simple woodworking tools. Designers can also make the flexibility in the panel. The installation work is going to be easy and fast. For this reason, it can save the cost. |

|

| 4) Excellent Fire- Resistance Property Its core layer is manufactured with Anti-toxic polyethylene core materials,having the combustion resistance property. Two surface layers are made of Aluminum, which is difficult to be burnt. Therefore, this is a kind of safe fireproofing materials, complying with fireproof demand in building code. |

|

| 5) Coating Evenness & Diversified Colors Since applied the chemosynthesis treatment and Henkel film technology, the adhesion between the paint and panel becomes evener, having multiple colors. There is more space for your choice to the color with individuality. |

|

| 6) Easy for Maintenance The anti-contaminant property has been obviously improved for Aluminum composite panel. Due to good self-cleaning capability, neutral detergent can clean the panel easily even though the pollution is very serious. |

|

| 7) Impact Resistance The impact resistance and toughness are strong. The coating layer can not be crashed when it’s bent. The panel can not be damaged when in a strong windy and sandy condition. |

|